The UV watch printer offers significant advantages in custom watch production, capable of printing on watch bands, watch dials, and watch covers with precision. It delivers high-definition designs, personalized styles, and long-lasting color durability, turning every watch into a one-of-a-kind masterpiece.

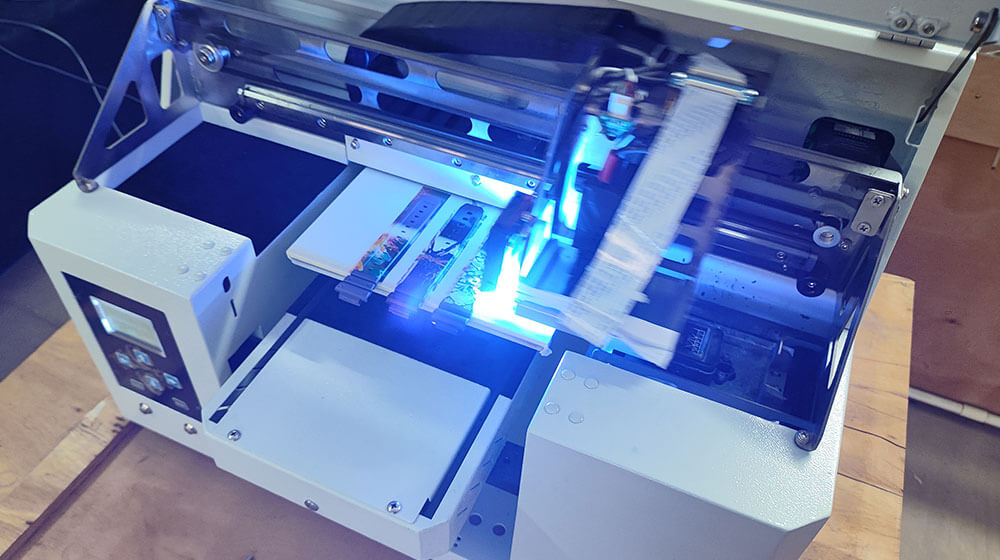

The operation is straightforward, users only need to upload their designs to the printing software, and the machine will automatically complete the printing process. It supports single-piece printing without the need for plate-making, allowing watch manufacturers and personalized gift shops to adapt flexibly to market demands.

In conclusion, the UV watch printer combines creativity, efficiency, and quality, making it an excellent choice in the watch customization industry.

Printing watch bands is relatively simple, as long as the operation steps are clear, the entire process is relatively smooth. It mainly includes the following key points:

Step 1: Place the watch bands on the UV printing platform and secure it using clamps or double-sided tape to prevent movement during the printing process.

Step 2: Open the UV printer software and import the design file.

Step 3: Start the printing process. The UV light will perform ultraviolet curing during printing, ensuring that the design dries instantly.

Step 4: After printing is complete, inspect the design’s color and clarity to ensure there are no misalignments or defects.

You can choose a suitable watch printer based on your business scale. For small-scale custom printing, a smaller desktop UV flatbed printer may be sufficient. However, if you need high-speed, high-quality batch printing of various watch straps or watch covers, we recommend that you choose an industrial grade UV flatbed watch printer. Options include printers with print areas ranging from 30×40 cm to 40×60 cm or even 60×90 cm.

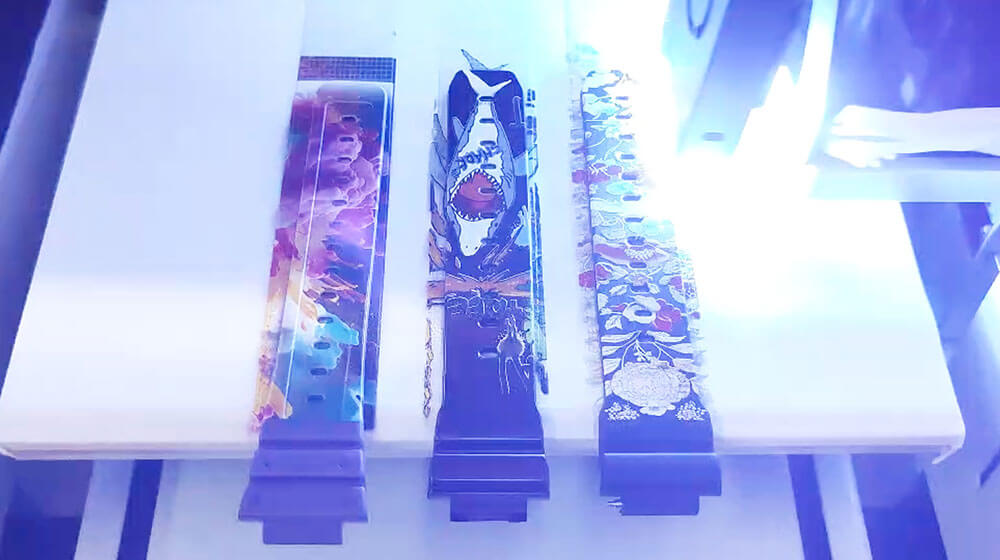

Our watch printer supports printing white ink as a base layer, followed by colored inks on top. This feature enables printing on watch surfaces of almost any color, allowing you to achieve vibrant and precise designs regardless of the base color of the watch.

By using a UV watch printer, you can directly print on the dial, cover, or even strap, turning an ordinary watch into a personalized high-end watch suitable for gift, promotion, and luxury markets.

The Watch printer can create intricate, detailed designs directly on the watch dial, enabling custom logos, patterns, and unique markings. This allows brands and individuals to craft distinctive, eye-catching dials that reflect their personal style or corporate identity. Fine details, gradients, and vibrant colors are achievable, enhancing the overall appearance of the watch.

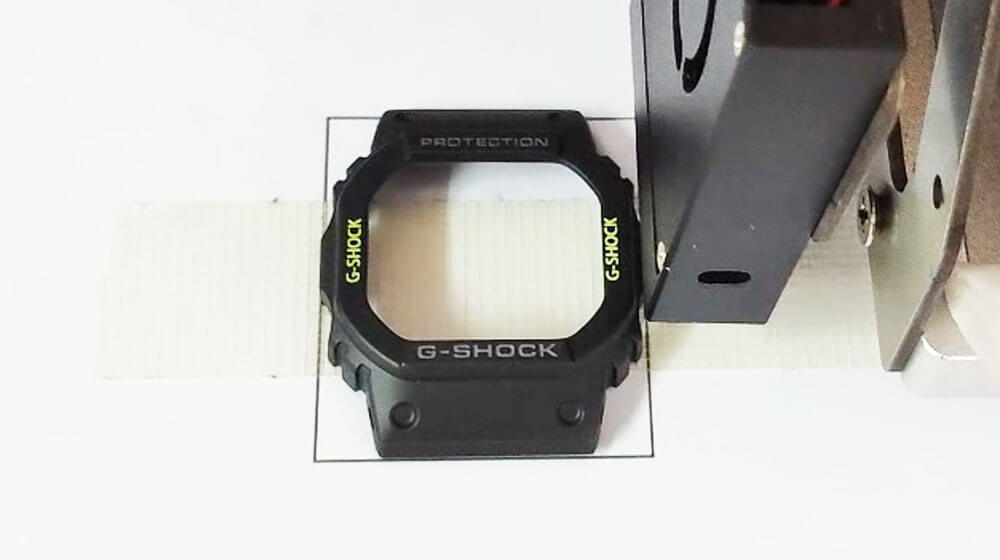

On the watch cover, watch printer can print text, serial numbers, or personalized engravings. This is ideal for adding branding, limited-edition markings, or custom messages that make the watch more meaningful. The UV printing process ensures long-lasting, scratch-resistant results that endure daily wear and tear.

Watch printer allow customization of logos and patterns on watch band. This will make the watch more fashionable and unique, whether for fashion purposes or promotional activities. The ink firmly adheres to the strip material, ensuring that the design remains intact and vibrant over time.

In theory, you can print any pattern on your watch because this watch printer uses high-precision printing technology that can flawlessly print both small text and intricate, colorful patterns. Here is some commonly printed content:

Custom company logos, brand names, and insignias can be printed on the watch face, case, or band, enhancing brand recognition and creating unique promotional products.

Watch printer can print serial numbers, model names, inspirational quotes, or personalized messages, adding sentimental or functional value to the watch. This is especially popular for limited editions or commemorative pieces.

Intricate patterns, artistic designs, and detailed images can be applied to the watch dial or band, allowing for fashionable and eye-catching designs that reflect personal style.

High-resolution images, such as portraits or meaningful pictures, can be printed directly onto the watch face or case, creating one-of-a-kind gifts or keepsakes.

Many custom watch printing services require a minimum order of 100 units because they typically use pad printing or screen printing technology, which often requires one to four molds for a single design. However, with a UV watch printer, there is no minimum order quantity. You can print any quantity, even just one for personal use.

Typically, people customize logo printing on the watch band, but it’s also common to see logos printed on the watch cover as part of the brand identity. Our Watch Printer is capable of printing logos on both the watch band and the watch cover, you can do the custom Logo printing job on watch also anywhere.

The printing process of UV watch printers is fast and efficient, and UV ink can instantly cure under UV irradiation without additional waiting, significantly improving production speed. At the same time, it is compatible with multiple materials, whether it is rubber, leather, or fabric, and can be easily printed to meet different styles and market demands.

UV watch printer can print vibrant and intricate designs directly onto rubber watch bands, commonly used for sports and casual watches. The UV ink bonds firmly with the rubber surface, ensuring that the print resists cracking, peeling, or fading even with frequent bending and exposure to moisture.

For leather watch bands, UV printing creates elegant, detailed designs while preserving the natural texture and feel of the material. The watch printer can produce high-resolution patterns, monograms, or branding that enhance the watch’s luxurious appeal.

Fabric watch bands, popular in fashion and casual watches, can also be customized using a UV watch printer. The printer applies durable, vibrant prints that adhere well to the textured surface of the fabric.

Our watch printer is suitable for printing on watch bands made from various materials, such as rubber, leather, and resin. Under normal conditions, the printed pattern on the watch band will not crack. It has strong adhesion and elasticity, allowing it to withstand a certain degree of bending and stretching.

Having a Watch Printer gives you the ability to fulfill nearly all custom watch requirements, including logos and designs. Whether you’re producing in large quantities, small batches, or even creating personalized pieces, a compact UV flatbed Watch Printer can accommodate all your needs.

I think you still have questions on the Watch Printer, you can send us any question right now and our professional team wil reply in short time!

WAYPRINTER is the leading manufacturer of UV and DTF printer, since 2007, we provide thousands of printers to customer all over the world.

Contact us right now to get more information, we will have people reply within 12 hours.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.